Safe, Sustainable and American-Made Stair Gates

•Posted on April 18 2019

When our founder Janelle Fitzpatrick first began the process of turning her invention into the brand that became The Stair Barrier, she was certain of two things: she wanted her product to be 100% manufactured in the USA, and she wanted to work with sustainable materials whenever possible. Through hard work and determination, she accomplished just that, creating a product that honors both a proud lineage of American workers and a conscious commitment to a sustainable future.

Coming from a family with a long-standing tradition of working for Ford, Janelle was raised knowing the value of creating American-made products.

“My cousins, my dad, my uncles, they worked for Ford. There was a great sense of pride in being able to put a product out there that was made by the community,” Janelle recounts.

She dreamed of a business that wouldn’t outsource its manufacturing, but instead create jobs for American workers. She instinctively knew that having the ability to establish personal relationships with the workers who made her product would make a huge difference in the quality and care that went into it.

This dream was easier said than done. The more people she talked to, the more she was told that her vision simply wasn’t feasible in today’s textile industry, where there is a huge disconnect between the product and the people who make it. “I was told I was going to have to go overseas...and that was the only way to do it.”

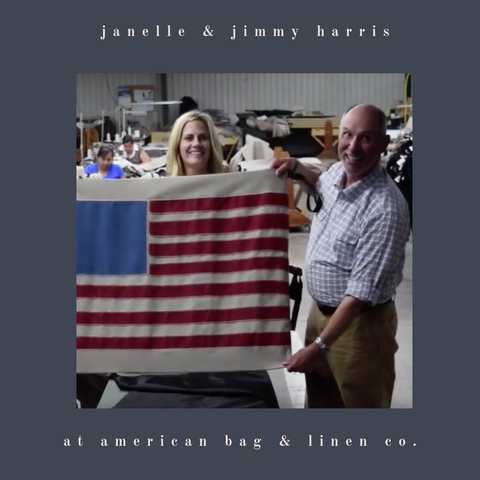

For awhile, life and work simply went on, until Janelle decided to go for it, despite the naysayers. That’s when she found American Bag Linen and Co., where each gate is now hand-crafted in Cornelia, Georgia. This allows Janelle to work closely with the men and women creating her product.

In fact, Janelle immediately had a positive connection with Jimmy Harris, the owner of American Bag and Linen Co. When she first pitched The Stair Barrier to him, he expressed concern that they may not have the space for it. In an interview, Jimmy remembers Janelle’s response to him and then immediately breaks into laughter, “Her response was, don’t hang up now, I already like you!”

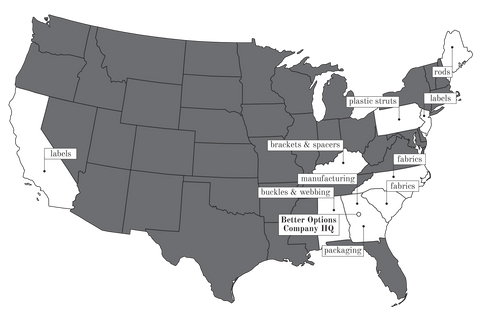

Today, every element of The Stair Barrier is sourced from American businesses, which not only qualifies it as a 100% American made product, but also makes it a more ethical option. While many companies “outsource” their pollution by using factories and manufacturers overseas, The Stair Barrier sources all of its components from the U.S., which reduces our carbon footprint on a global scale.

The product labels are produced in California; the rods in Vermont; the fabrics are milled in the Carolinas; the plastics in Pennsylvania and Kentucky, and the packaging in Georgia

Janelle didn’t stop there. In a world plagued by astronomical waste where nearly everything is disposable, she wanted to find a way to create her product ethically and sustainably within the textile industry. To solve this problem, she turned to an innovative fabric called REPREVE.

On average, humans buy a total of one million single-use plastic bottles every minute just within the United States. Of that staggering number, only about 23% get recycled. Thankfully, companies like Unifi, the parent of REPREVE, have a solution to repurpose the ones that do make it to the recycling bin and help end the vicious cycle.

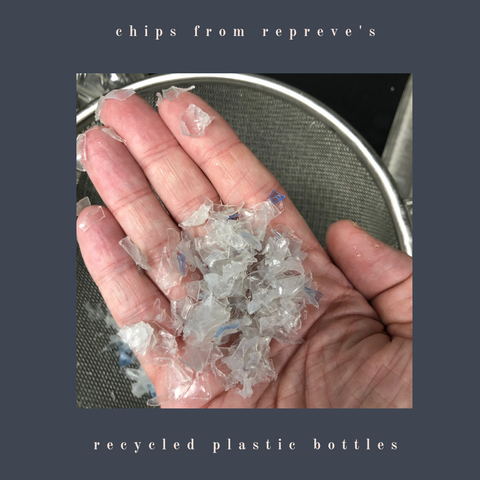

Unifi creates a fiber called Repreve from recycled water bottles. Repreve’s website boasts that they’ve recycled 14 billion water bottles, with the goal of hitting 20 billion by 2020. Next to their goal, an encouraging counter rapidly ticks upward. By the time you’re finished reading this post, it will have increased by several thousand.

The recycled fiber Repreve creates can then be woven into fabric used by many leading brands, including, of course, The Stair Barrier.

Janelle has personally visited the Unifi plant in Yadkinville, North Carolina, where three million water bottles are processed and repurposed every hour.

“The manufacturing process is insane. I think I’ve become a manufacturing junkie. It is so cool to see how things are made,” Janelle says of her visit.

She’s seen the pond that powers the plant, and she’s met the two plant managers -- two women who’ve been there over 40 years, who Janelle describes as “absolutely amazing” and “really inspirational.”

In order to spin fabric from plastic, Unifi’s facilities break the water bottles down first into flakes and later into pellets. The pellets are then turned into fibers, which are spun into yarn that can be woven into a variety of different fabrics.

Of the newest line of fabrics for 2019, The Stair Barrier is proud to offer three gates made from Repreve, including Burlap Charcoal, Burlap Mocha, and Burlap Khaki.

Reminiscing and laughing about her first phone call with her manufacturer in the north Georgia mountains; holding the plastic pellets in her hands that will eventually become the same fabric used in some of her products; walking away from a complex manufacturing plant feeling totally inspired by the two women who run it -- it’s these interactions that hold the very spirit of camaraderie and personal connection that Janelle sought from the onset when The Stair Barrier was just an idea.

When you purchase a Stair Barrier, you can be assured that you’re supporting American workers, American manufacturers, and American business owners who are invested in an eco-friendly future.

Comments

0 Comments

Leave a Comment